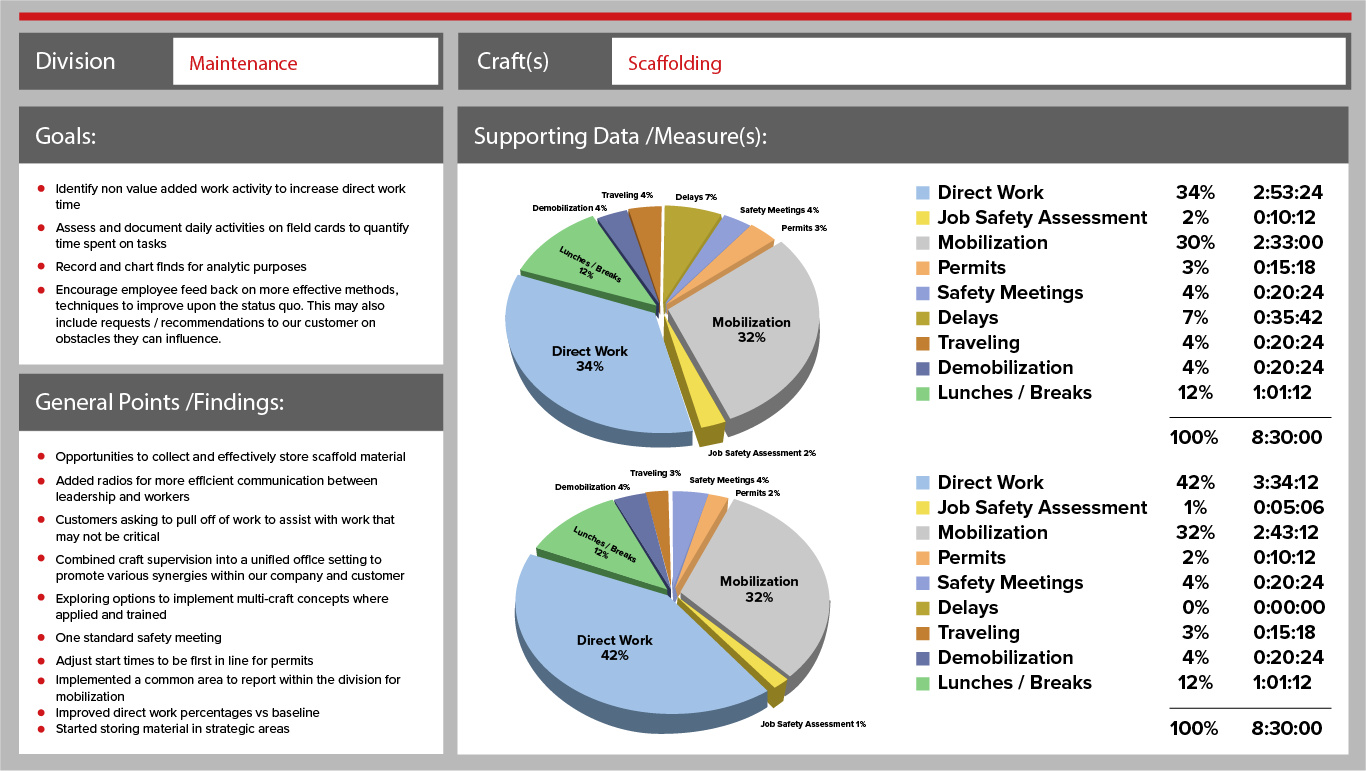

Behavior Workforce Studies

- Working “faster” is not the answer to creating a more efficient operation.

- Efficiency gains are more safely achieved

through increasing direct work (i.e. tool time). - We have mastered the ability to study dependencies in industrial

work streams and identify opportunities to increase direct work. - Our process is designed to capture honest feedback from the workforce

and using that feedback to reduce or remove existing inefficiencies. - Day in the Life of (“DILO”) studies are a powerful observation tool

that allows us to analyze the daily activities of each individual worker. - We provide customers with greater transparency of the workstreams,

and recommended improvements based on our years of proven results. - Our vast experience in this field has allowed us to perfect

our process and achieve quantifiable results.

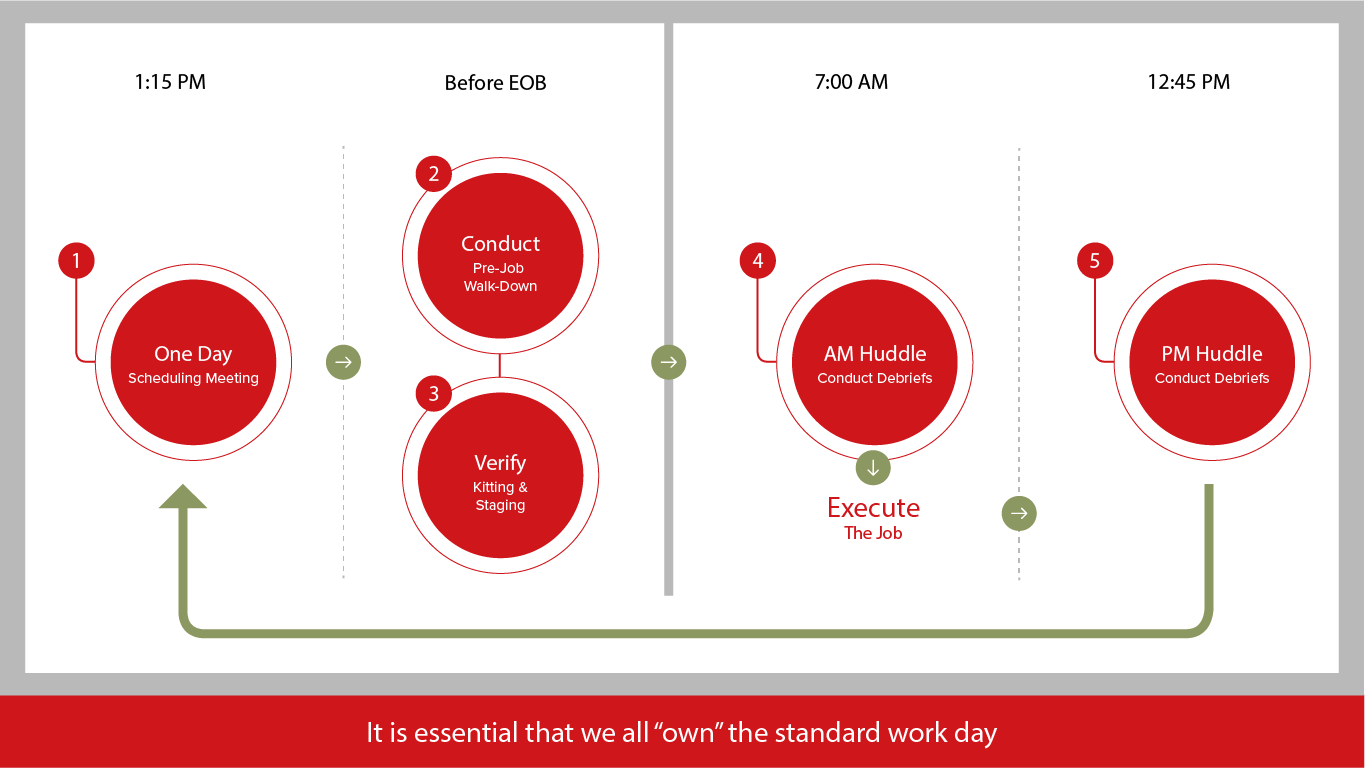

Field Cadence Programs

- Through decades of craft experience we have learned how to create an efficient cadence or rhythm in the field, resulting in greater efficiency and safety across a field workforce.

- Managing an industrial workforce effectively requires clear and continuous communication and positive reinforcement.

- Our approach includes scheduled field meetings or “huddles” that serve as strategically timed checkpoints during the typical workday.

- We tailor the length, duration, topics and schedule of these huddles

to each industrial setting to achieve the optimal benefit.- Better preparation for our workforce

- Safer work execution through better anticipation of risks

- More consistent and efficient standard workdays across all crafts

- Better transparency of the daily tasks from start to finish

- Improved workforce confidence and productivity through

micro training sessions

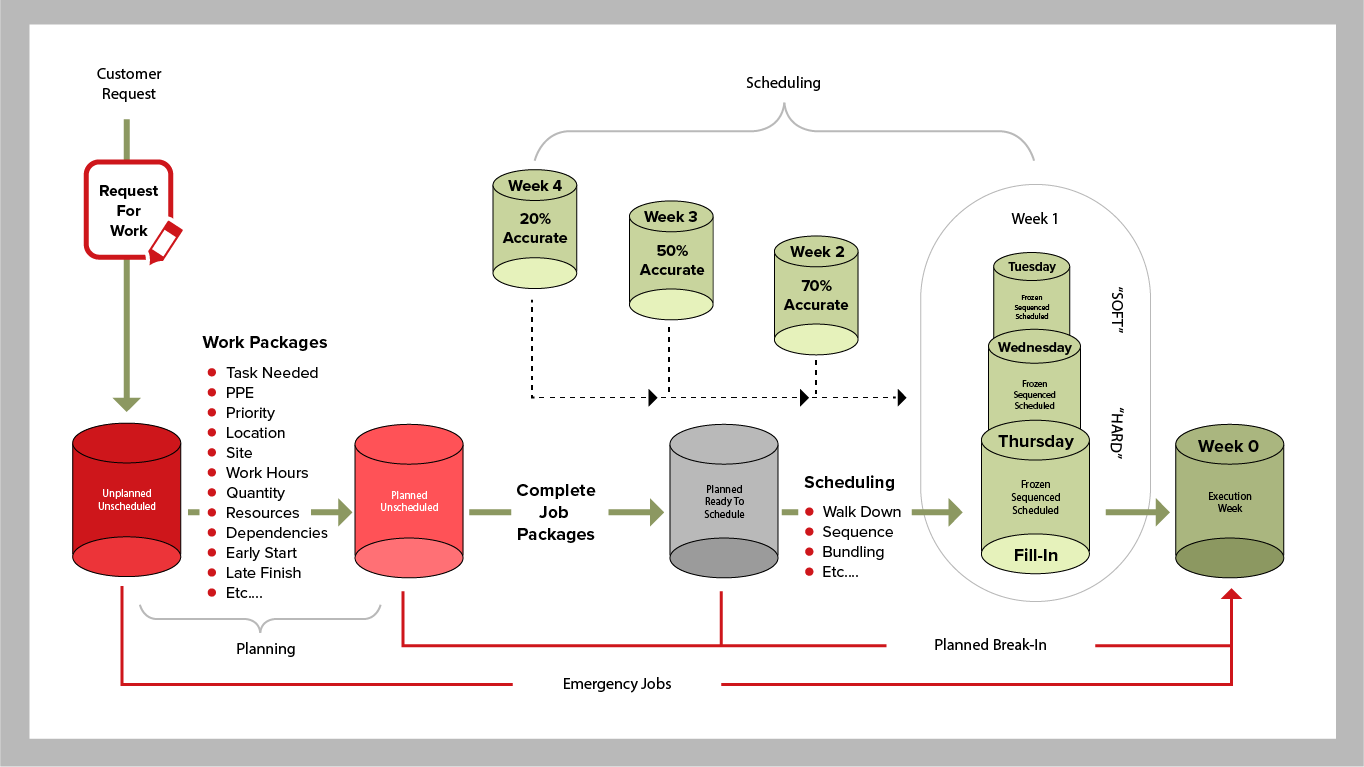

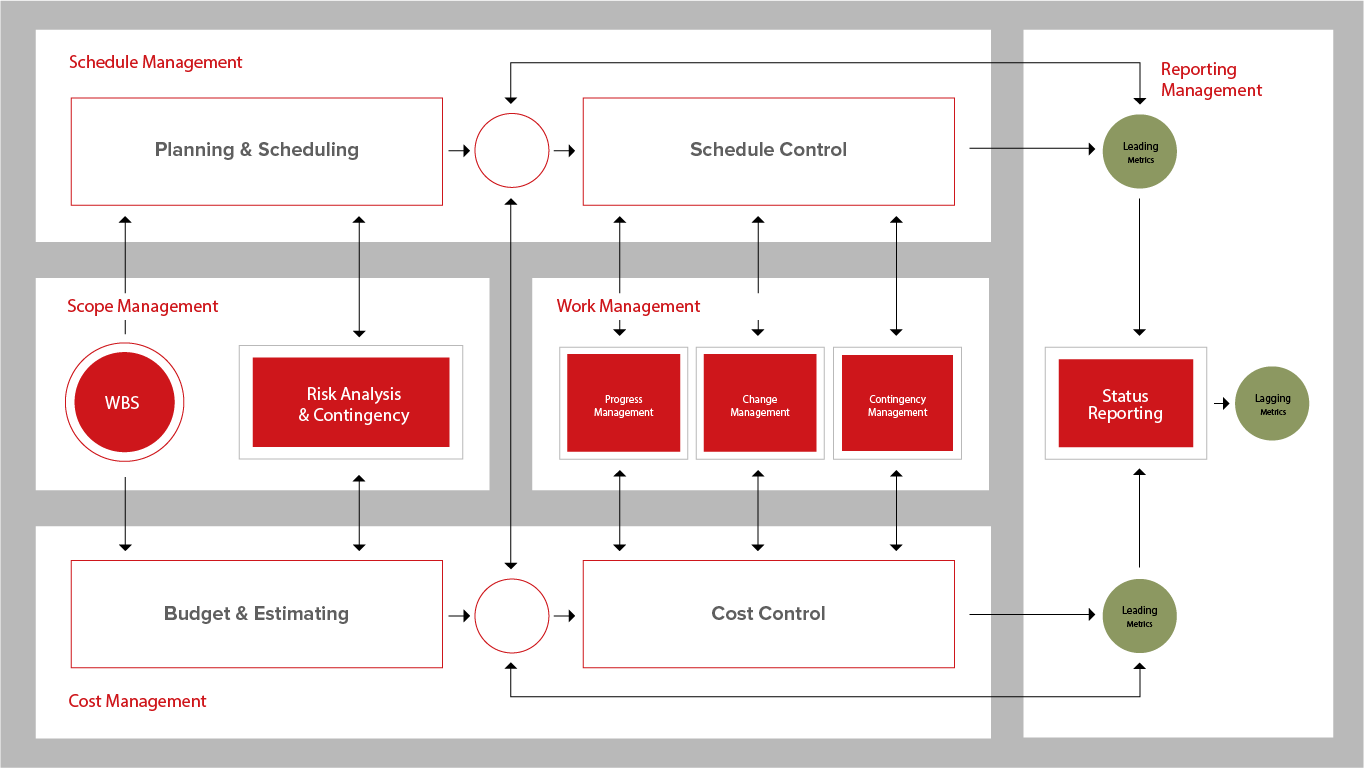

Integrated Planning & Scheduling

- We optimize work efficiency by integrating all aspects of

planning and scheduling activities. - Earlier, better coordination has numerous tangible benefits.

- Increase planned work and reduce inefficient reactive work

- Better safety through earlier anticipation of high-risk activities

- Greater direct tool-time from the workforce

- Higher utilization of equipment and assets

Our proven approach to integrating planning and scheduling activities is highly effective and leads to better safety and cost savings for our customers.

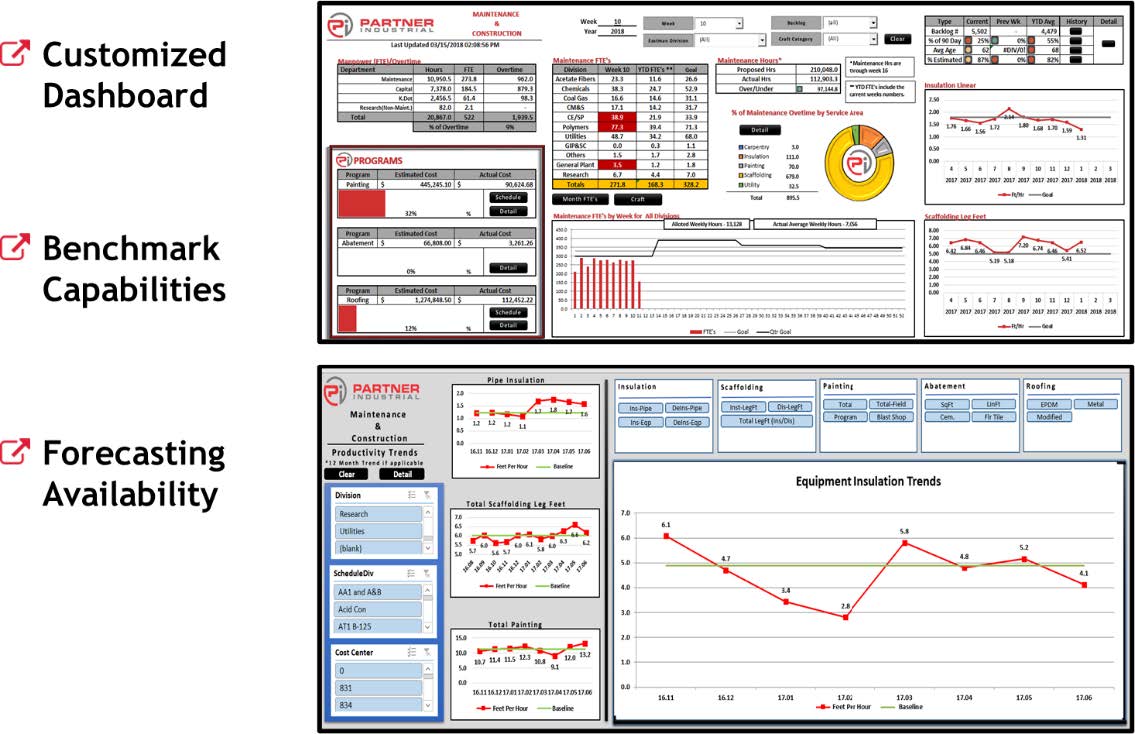

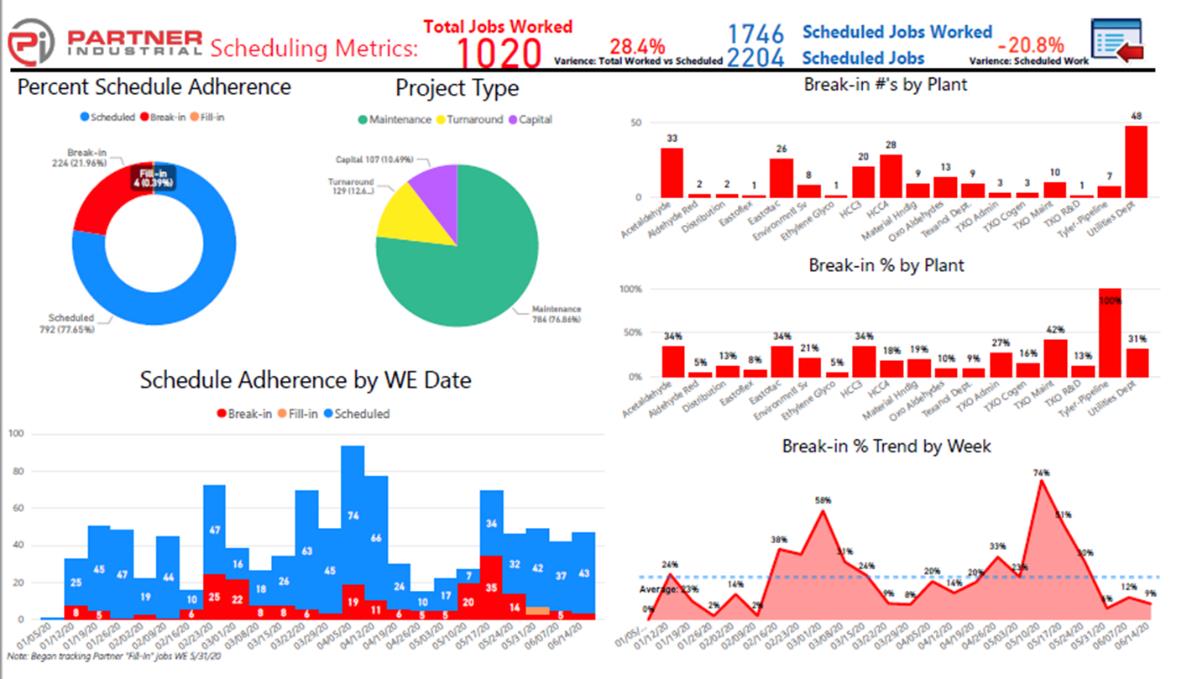

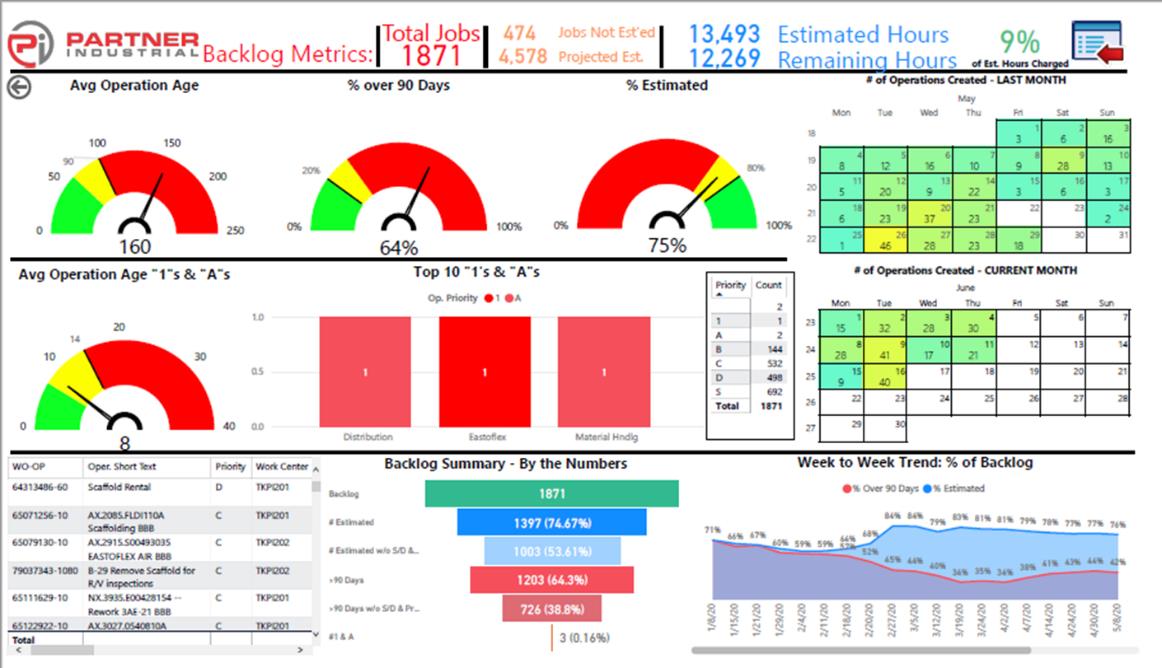

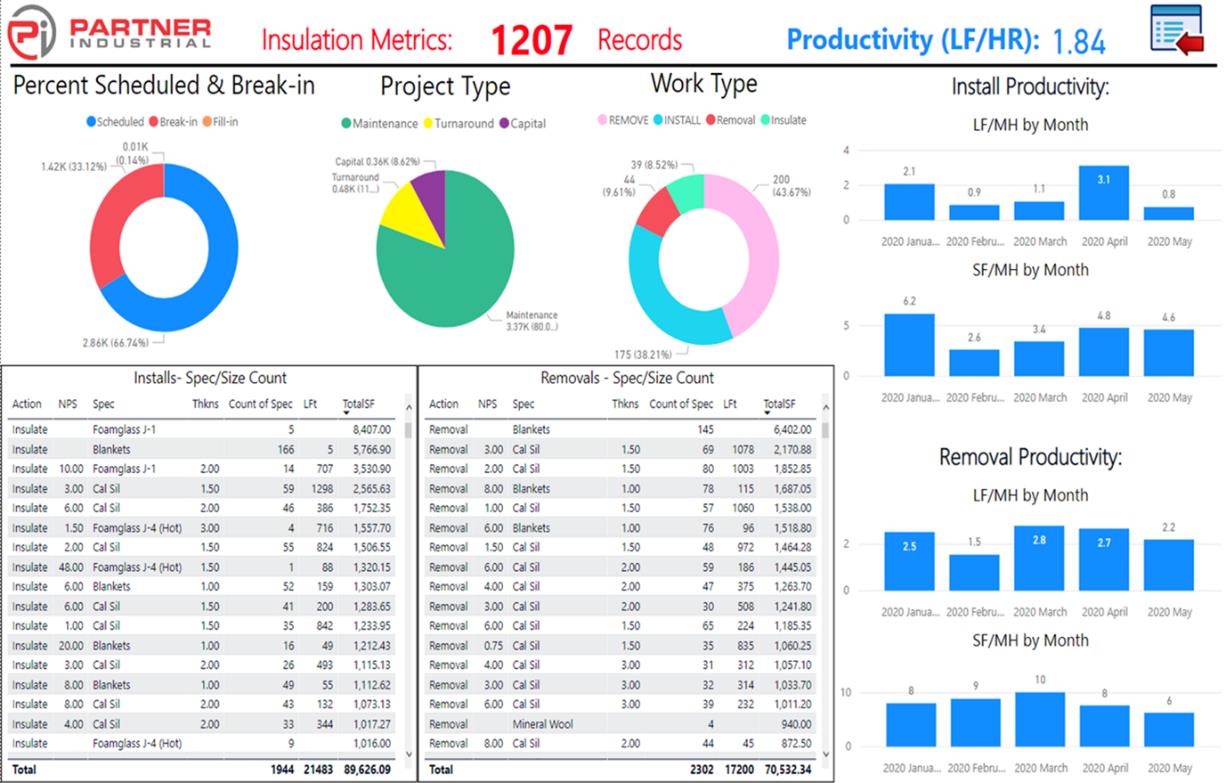

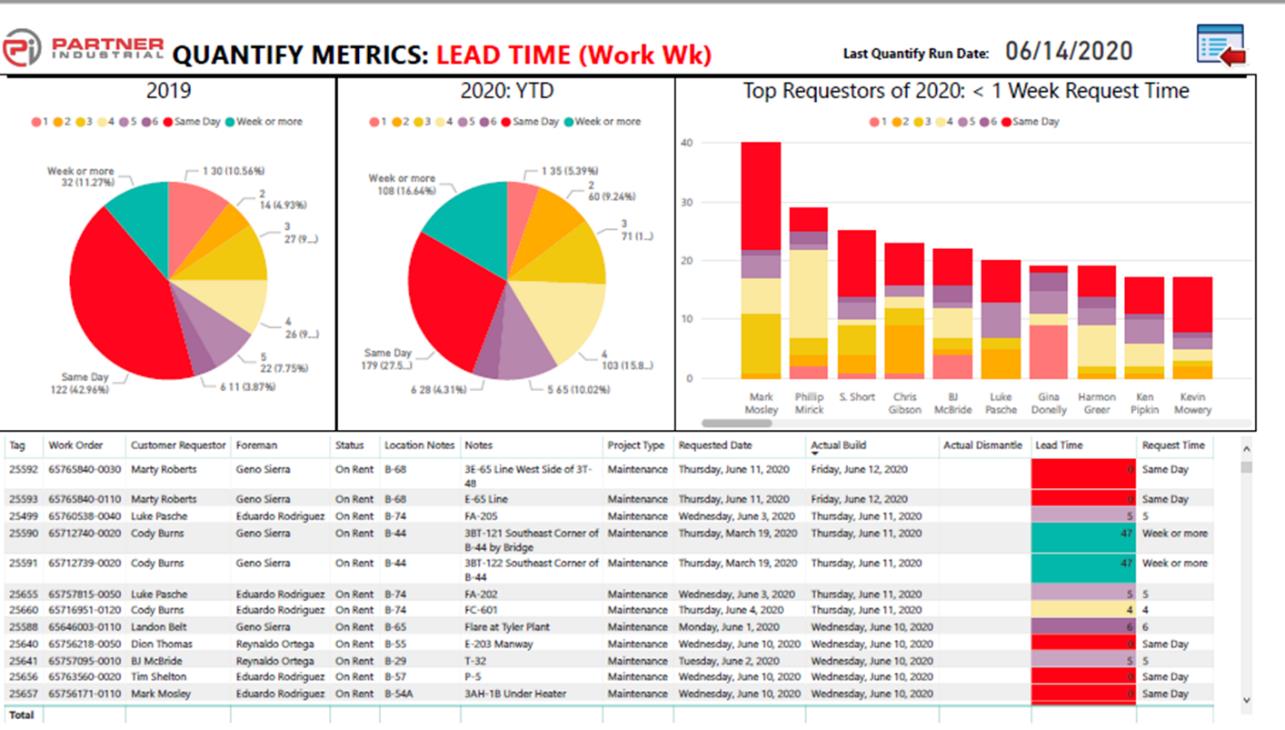

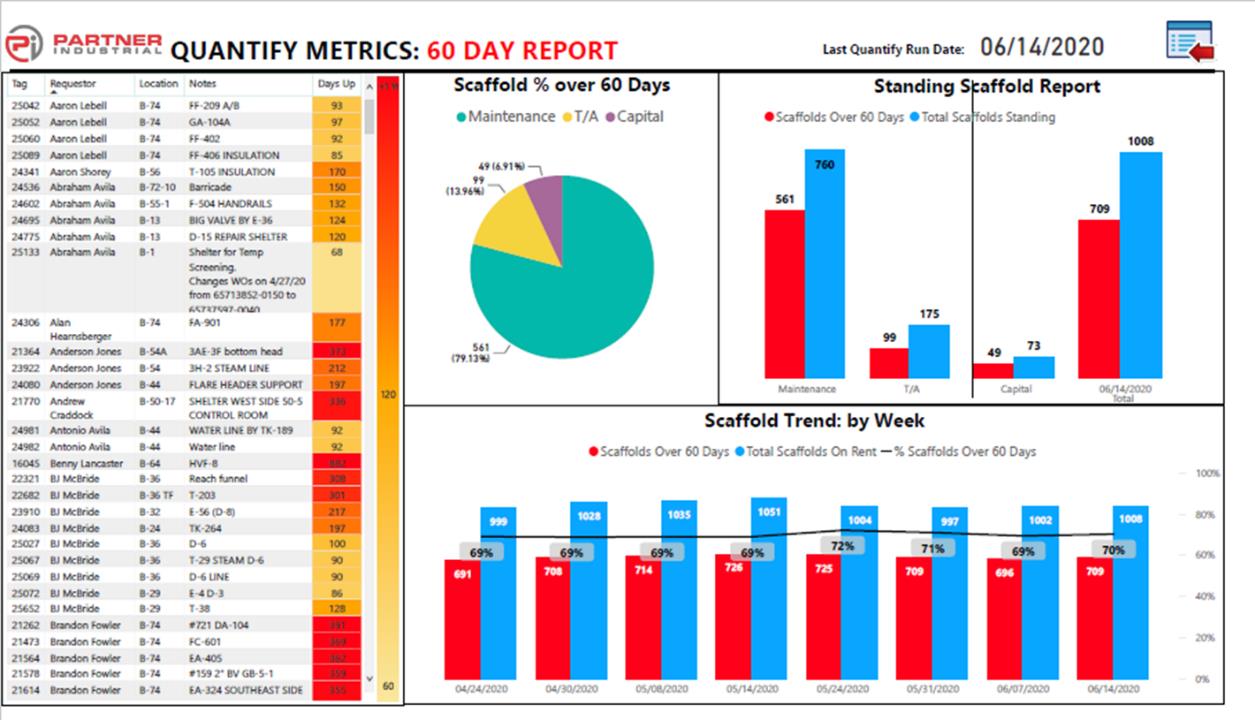

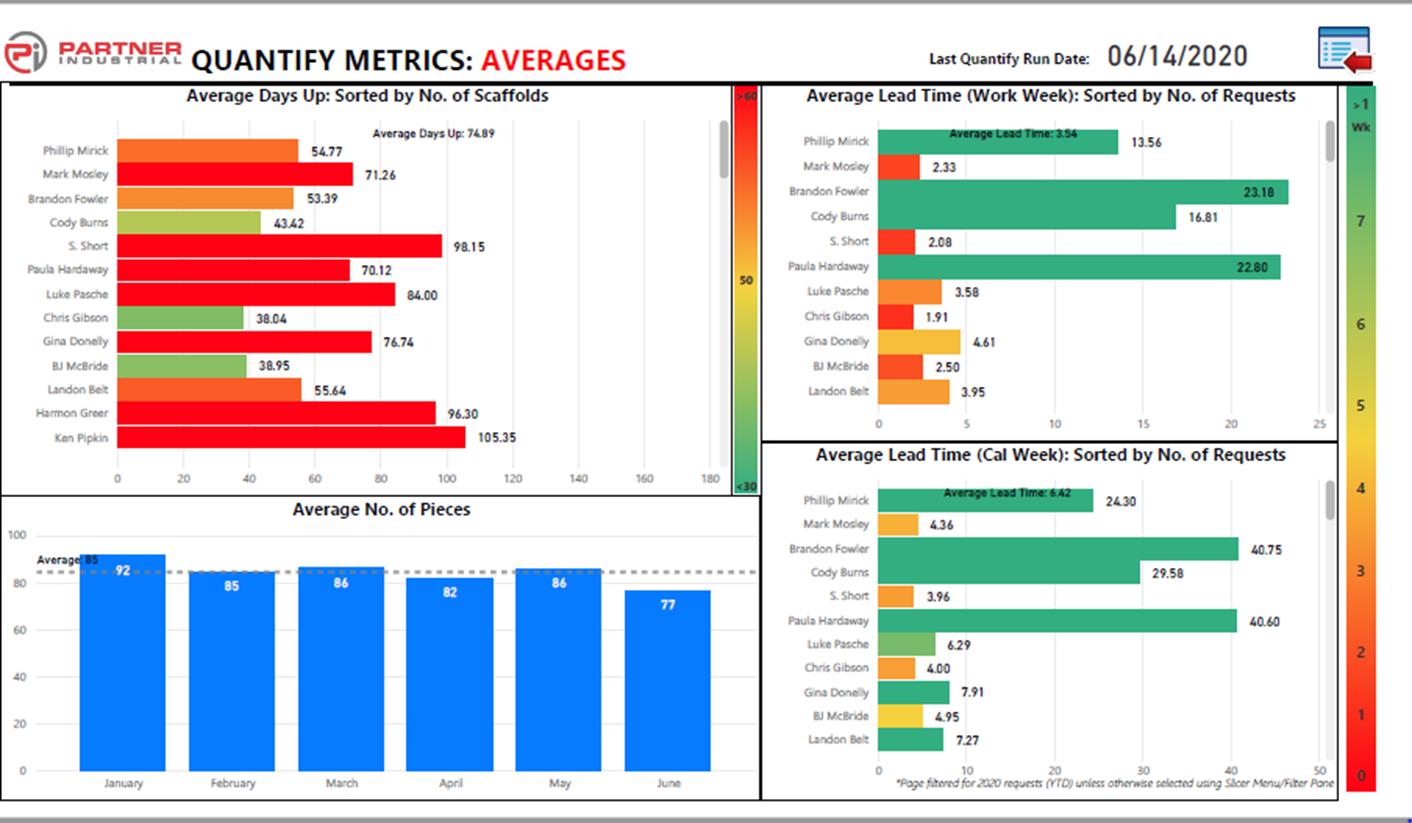

Actionable Metrics & Analytics

Having the right data is critically important to optimizing maintenance activities, mitigating operational risks, and reducing total cost of ownership.

Advanced analytics can be used to predict events, fine tune efficiencies, improve workforce and asset utilization, and create more operational transparency.

Not all data is helpful, which is why we apply decades of experience to help our customers determine which metrics and measurements will be the most impactful and actionable.

Mobile Field Technology

- As the need to achieve better maintenance efficiency and

productivity at the field level has increased, the introduction of technology has become more appealing. - We have experience in implementing hand-held mobile devices into an industrial maintenance setting across a large workforce, resulting in process improvements and staff reductions.

- The key to introducing new technology into an industrial workforce is to clearly understand the benefits and risks:

- Possible Benefits – efficiency improvements, redundancy elimination, cost reduction, streamlined data streams and processes, etc.

Possible Risks – workforce rejects the technology, creates more disruption than benefits, high cost, etc

We help our customers evaluate available technologies and determine which technologies will provide the best value and least disruption.

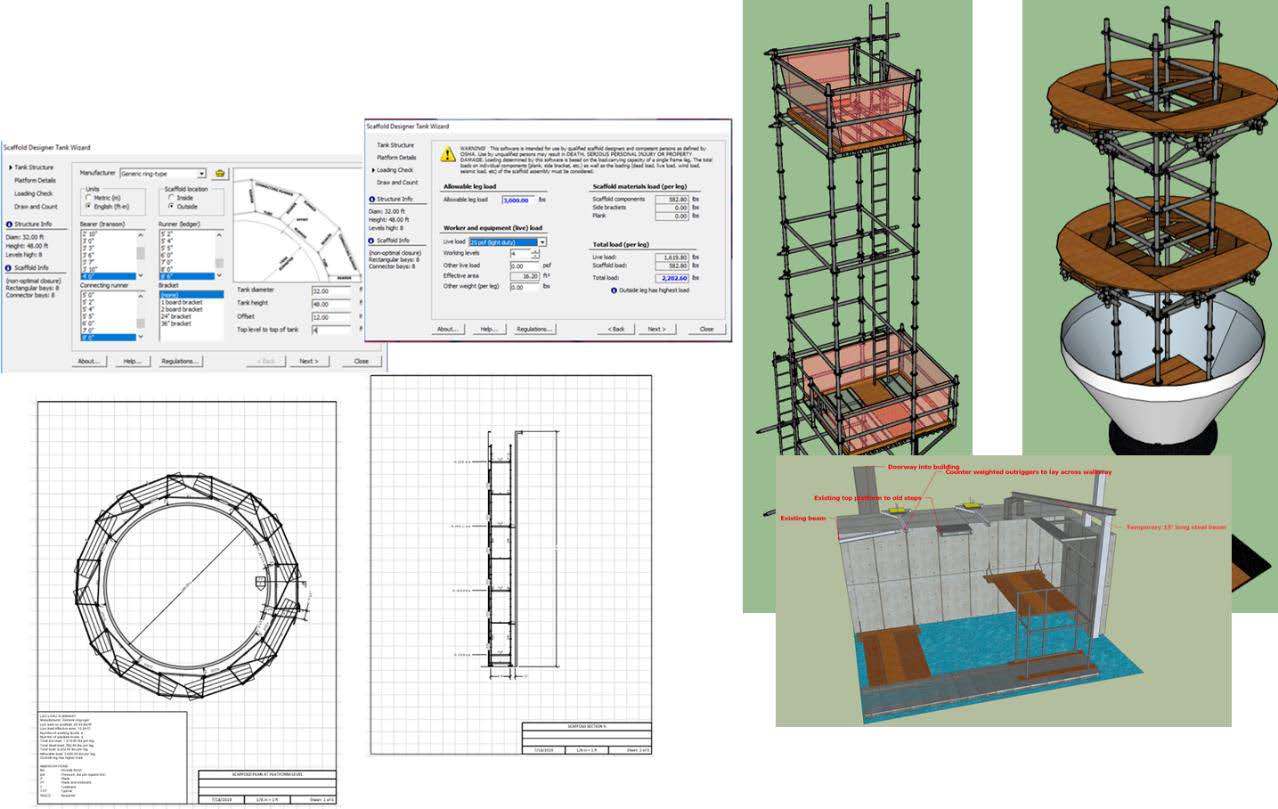

Scaffolding Design & Management Program

Fundamentally changing the way that scaffolding is planned, executed, and managed

Our program combines decades of scaffolding experience with proven software technology to create an advanced approach to traditional industrial scaffolding

- Better planning

- More accurate forecasting

- Measuring and managing to benchmarks

- Reduction of waste and reworks

- Reduction in non-scaffold trade labor inefficiencies

- Actionable data, metrics, and KPIs

Our comprehensive and advanced scaffold program is designed to maximize equipment transparency, increase asset utilization, and reduce equipment costs.

Planned Maintenance Programs

- Beyond scaffolding, we also offer sophisticated management programs across many other crafts

- All of our management programs are focused on improving work efficiencies, more accurate forecasting, longer-term planning, timely data and actionable metrics